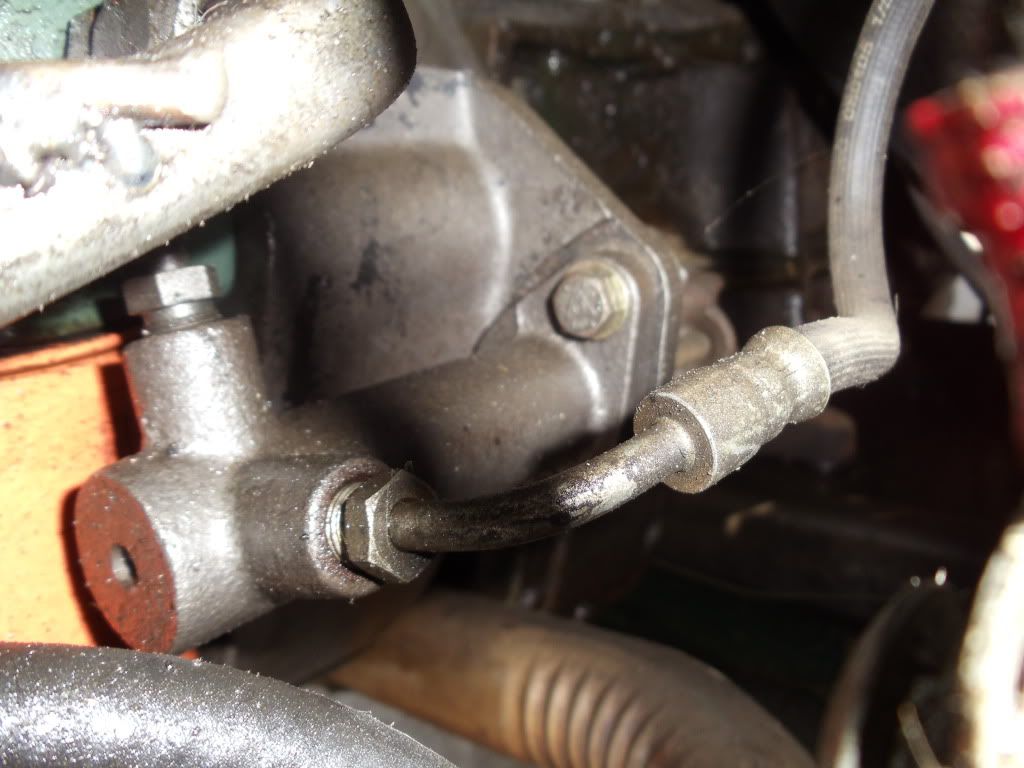

ive had a stock chevy set up hydro clutch in my kaiser for a while now, i bought a hydro clutch bell housing, slave cyl, master cyl, and line, it was an awesom fit. i just shortened the master cyl rod an threaded it for a small heim joint. this was a few years ago, i was probably 16 when i did it so anyone could lol

Reply With Quote

Reply With Quote