Not necessarily "stock" as I simply want to reproduce one for myself.

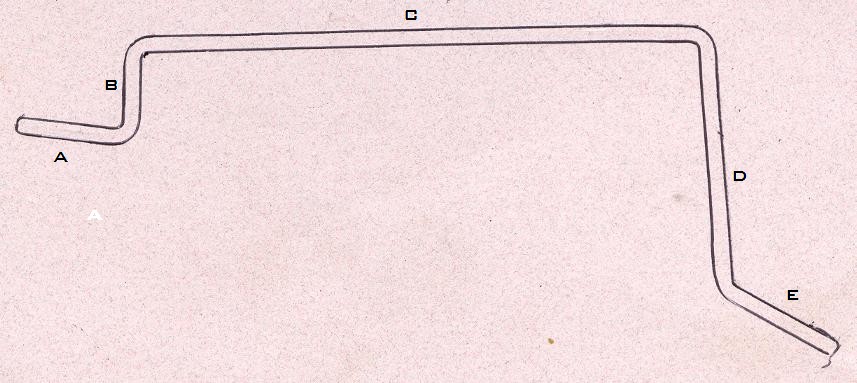

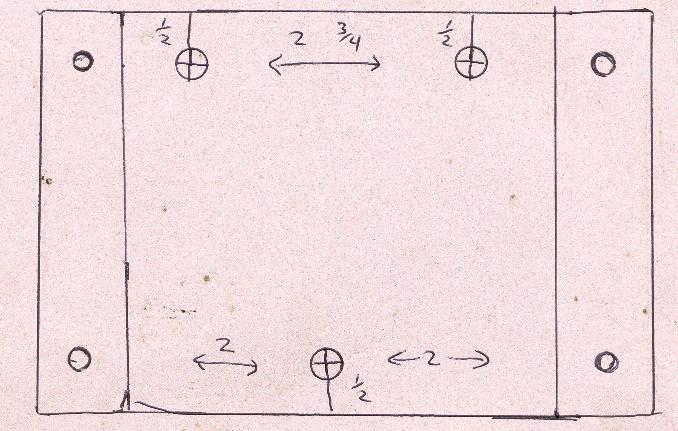

I have the means, (brake,shear etc) but was curious if anyone had "working drawings" with the correct bend angles, edge-flange lengths, or hole dimensions already done for the hood blackout light mounting bracket for the hood.

Will be making it either out of 20 or 16 gauge CRS sheet as that is all we use at work (20, 16, and 11 gauge is our only stock sizes)

(bracket that the blackout light and hoop assembly bolt too)

I do not have a blackout light yet so I cant do those holes... and I am either going to make a paper template and then transfer over or was curious to see if anyones been down my path yet.

Reply With Quote

Reply With Quote