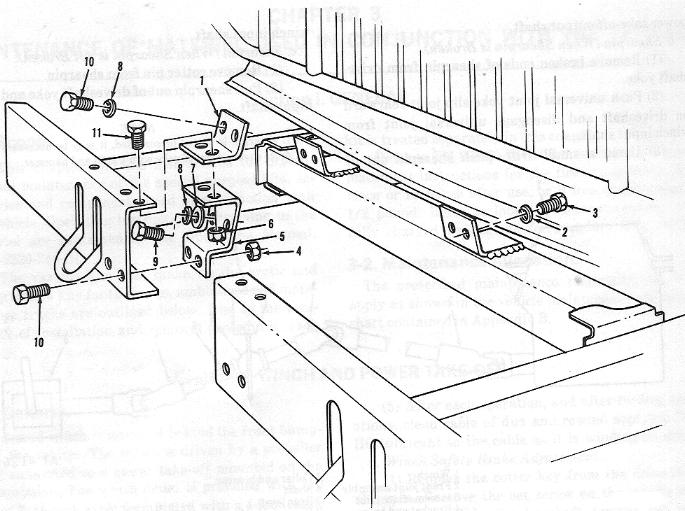

We are finally done picking the engine up and down in Pistolnut's truck. So, now we can mount the winch. We have all the pieces along with the fasteners. Sitting in a pile in the bed. I have the one exploded view I can find in the manuals as a map. But, I can't remember what order we took it apart 2 years ago and I have all different students from them as well.

Anybody out there care to recommend an order to putting the parts on the truck that works? Thanks.

Reply With Quote

Reply With Quote